Working with a manufacturing company within the oil & gas industry, the company manufactures engineering products that are highly customised to each installation i.e. no two products are the same. The saes team were only too keen to start with a clean piece of paper for every design, in an effort to (apparently) give customers exactly what they want.

As a result, the standard product lead-time was >22 week. It had always been that way – everyone knew it (and therefore accepted it).

Problem Owner: Engineering Director

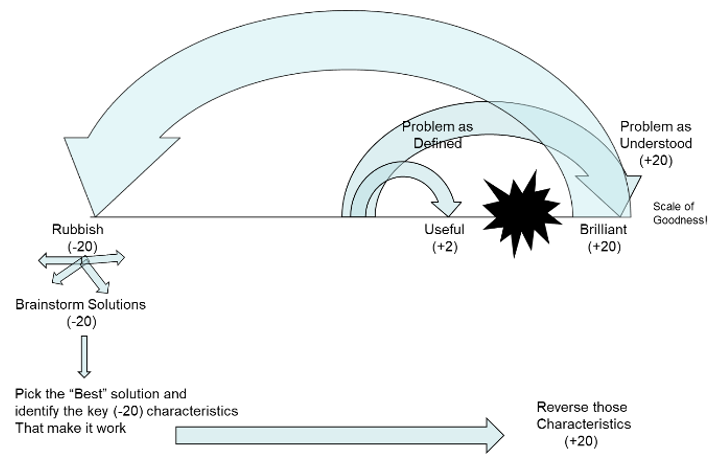

This will score, say, +2 on the “scale of goodness”. We would like it to be +20, but there are mental blocks in the way. The challenge is to get around the blocks; read on …

Intermediate Impossible – brainstorm solutions to the reversed problem, then pick the “best” (-20):

Employ an external consultant to constantly build complexity into the specification on behalf of the client. In addition, encourage the sales team to constantly chivvy the customer for variations in parallel with the engineering process.

Characteristics that make this work (-20):

Reverse these characteristics (+20):

Define very low level base model, with lots and lots of upgrade options (all of which are standard, but the final product for a customer feels like it is bespoke) – including low cost “surprises and delights”. Engineering of simplified, flexible piece-parts. Rather than everything being engineered for a precise, specific, fit – design in slots and tabs for flexibility, allowing customisation to be built in within the Manufacturing process (rather than Engineering).

Then … a bonus emerged in the thinking – designing these flexible “slot and tab” components means that the assembly process has in-built latitude (or self-jiggling!) within the manufacturing process, therefore taking significant time out of both Engineering and Manufacturing.

Overall product lead-time reduced from >22 weeks to <8 weeks.